Rumored Buzz on Glazed Spandrel Panel

The system is suitable for rapid track installment where risk-free methods of work are needed. The AA265 has actually been specifically created and developed by Kawneer, with installment contracts taken on in cooperation with its network of authorised suppliers. The AA265 has been examined as well as certified in accordance with the CWCT Sequence B 2006 Criterion for Systemised Building Envelopes.

Whether you require Glazing Infill Panels, Spandrel Panels, Darkness Boxes, Soffits, Copings, Backpans or Flashings, Embury Company will provide on schedule as well as on budget plan. Let our group help as well as guide you through all of you metal panel needs. Our State of the Art Facilities allows us to function flawlessly with any sort of product and also get you what you need.

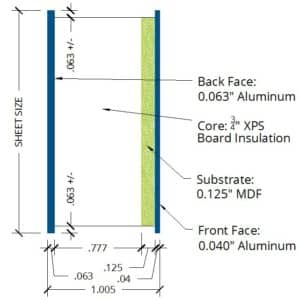

The panels are offered from.016 to 3/16 (.1875) of an inch, utilizing Light weight aluminum, Stainless-steel, Galvanized or ACM. Whatever the density, material or finish Emburite Panels will certainly answer the need - kawneer spandrel panel metal spandrel.

Lurie Panels, a country wide recognized panel laminator and fabricator, offers a variety of architectural strugglings with, stabilizers and also cores for facias, spandrels windows as well as stores. Infill panels also are available in a variety of exterior architectural products including coil covered and post painted Kynar 500, light weight aluminum and also steel, porcelain, stainless steel, spandrel glass, Fiber Reinforced Plastic (FRP) as well as a lot more.( 414) 371-2602AR/ LA/ MS.

The Basic Principles Of Glazed Spandrel Panel

This considerable range has actually been developed for use in curtain wall tasks where the specifier is looking for either to match the non-vision spandrel panels to the vision location of glazing or to offer a contrast to the vision location glazing. The panels are readily available to match the entire series of aesthetic impacts produced by the use tinted or reflective glasses, and also can be provided with or without insulation, and in solitary glazing in addition to Insulating Glass Unit type.

The colour choice can either complement or contrast relying on the finishing or colour of the external glass. Spandrel Glass can be shielded with a selection of materials to fulfill even one of the most exacting of criteria. Pilkington Spandrel Glass is produced spandrel glass details in 7 basic colours, supplemented by a selection of white choices.

British Basic references connect to BS 4904:1978: 'Specification for external cladding colours for building functions', although much more colours have actually been matched to BS 5252: 1976. Spandrel panels are not made to be checked out in transmitted light as well as the resultant colour will vary depending on the density of the base glass.

10 Simple Techniques For Glazed Spandrel Panel

With raised ceramic coverage on the glass, screen printing assists to regulate heat as well as light transmission. The shading coefficient of clear and body tinted glass is lowered, thus allowing better adaptability of option and also style.

Drape wall as well as store glazing systems are typically a thin, non-structural outer faade component of a structure that can span several floorings or be integrated into a punched opening. Polishing systems function greatly as air and water vapor obstacles, standing up to air or water infiltration as well as accommodate structure and system activity induced by wind, thermal, and seismic forces.

As such, lightweight materials can be used in their growth. Commercial glazing systems are normally created of aluminum-framed wall surfaces with glass, steel panels, louvers, operable home windows or vents, or stone veneer infills. Building envelope professionals will typically advise designers on curtain wall surface and store front requirements for building activity, thermal expansion and also contraction, water diversion, and thermal performance.

Nontransparent glazing, metal panels, MCM (steel composite materials) panels, or site web insulated laminated panels are commonly used as spandrel infill. When insulation is utilized inboard of the spandrel infill, an air area is consistently introduced to protect against thermal damage to the spandrel infill (fire rated spandrel panel). Regrettably, the air area can provide a chance for condensation to develop on the indoor face of the spandrel infill.

Fire Rated Spandrel Panel - An Overview

Need to poorly made spandrel conditions be left neglected, condensation can cause wetness or aesthetic damages to the spandrel panel discover this and/or interior surface areas. When condensation forms at the spandrel infill of a glazing system, numerous types of damages can occur, and the results of condensation can be far-reaching. Along with dampness damages and also microbial growth, condensation growth on spandrel infill can also have an adverse effect.

One way to delay the formation of condensation on the glazing system spandrel infill is to utilize the structure COOLING AND HEATING system. By boosting air flow near these areas, more warm will be transferred to the assembly and increase indoor surface area temperature levels. One more means to make use of the HEATING AND COOLING system is by lowering the interior loved one moisture established points with regard to outside temperature.